Made to measure for your mill site

Comeback

The transition away from fossil fuels to renewable energies is also helping hydroelectric power plants to achieve a renaissance. In contrast to wind or solar energy, hydropower allows the generation of base-load electricity that is reliably available.

The most powerful waterwheels, the so-called “top-sheeted” waterwheels, have been known since the Middle Ages and are supplied with water from above.

The field of application of top-shear waterwheels is at gradients of 2.5 m to 10 m and water quantities of up to 2 m³/s. Typically, slopes of 3 to 6 m and water flows of 0.1 to 0.5 m³/s are encountered in operation. Former mill sites usually have potentials between 2 and 10 kW.

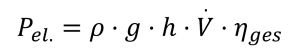

The output of a hydropower plant is determined by the water supply and the head as well as the discharge behavior of the watercourse, from which the hydraulic potential and the electrical power (kW) that can be generated at the respective site can be determined. Roughly, the power of an overshot water wheel is calculated with the following formula:

where here the electric power [W], the density of the water [kg/m3], the gravitational acceleration [m/s2], the head or wheel diameter [m], the volumetric flow of the water [m3/s], and the total efficiency of approx. 0.7.

Benefits

In contrast to turbines, water wheels run without water level and flow control in the partial load range without any significant loss of efficiency in the case of strongly fluctuating water quantities. They are also mostly insensitive to water pollution. Top-bladed waterwheels can therefore do without rakes. As a rule, the biological continuity of watercourses is maintained. Due to its low speed, there is no risk of injury to fish.

Technology

In order for these advantages of the waterwheel to come to fruition, it was necessary to translate the concept of the waterwheel into the modern age in order to equip waterwheels specifically for economic power generation.

The low speeds of the waterwheels of typically 5-12 rpm (circumferential speeds of approx. 1.5m/s), which are inherent to the principle, have to be translated to the generator’s usual speed level of 750 – 1500 rpm. This requires a gear ratio of about 1:100. The low speed requires gearboxes that can permanently withstand extremely high input torques (e.g. 2000 – 5000 Nm at DRad = 3 m). Modern planetary gear units fulfill this task with efficiencies of over 90%.

Construction

The modern age has also arrived in terms of materials and production technology. Stainless steel and aluminum as well as CNC-controlled sheet metal processing replace the work of the carpenter.

Expensive custom-made products to adapt to the geographical conditions of the respective location are no longer necessary. Our modular system, based on a manageable number of standardized elements (shaft; bearing; hub; spokes; integral cell elements forming the wheel rim to hold the water), allows the individual series production of modern, cost-effective water wheels for the economic generation of electricity.

Operation

Unmanned operation by means of remote maintenance and control also contributes to this. Status queries and interventions in operational processes, such as stopping the wheel, can be carried out conveniently from home via cell phone or PC and Internet.

For practically all flowing waters in Germany and Europe, reliable annual discharge series in decade cycles are available from hydrological institutes. The feed-in to the public power grid and its remuneration is legally guaranteed for 20 years according to the EEG. With the last EEG amendment, the feed-in tariff for small hydropower plants up to 500 kW was set at 12.15 cents/kWh in 2021. On this basis, well-founded investment decisions can be made.

Economic efficiency

Assuming an availability of 85%, which corresponds to an annual operating time of 44 weeks or 7446 hours, around 75 MWh of electricity can be generated with 10kW continuous output. This corresponds to a gross yield of 9434 euros per year. From this, about 1500 Euro for maintenance and operation have to be deducted.

This form of sustainable energy production is not only of interest to holders of old water rights and mill sites, but also to investors. An exemplary potential study carried out by the state of North Rhine-Westphalia is intended to show them the way. In Germany alone, about 20,000 unused former mill sites, which cannot be economically developed with turbine technology, can be reactivated.

In most cases, the old millrace and millpond are still in place, and the weir can also be repaired at a reasonable cost. Approval procedures are relatively simple, as long as the old legal status (operation of a water wheel) is desired.

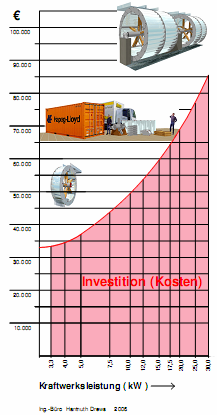

Investments

The investment costs for the machine set (waterwheel, bearings, gearbox, generator, control cabinet with feed and control technology) of an overshot waterwheel from our company are between 3,000 and 10,000 euros per installed kilowatt, depending on the output, with a 10kW system costing 5000 euros/kW. If the power is halved to 5kW, the costs increase by about 50% to about 7500 Euro per installed kW and decrease by about 30% to about 3500 Euro/kW if the power is doubled to 20kW. This cost degression is illustrated again in the figure below. In addition, there are investments for water-structural measures on site for water catchment, foundation, and inlet which, depending on the scope, can be estimated at 50-100% of the costs for the machine set. An amortization period of approx. 10 – 12.5 years seems to be realistic for a plant with 10kW capacity.